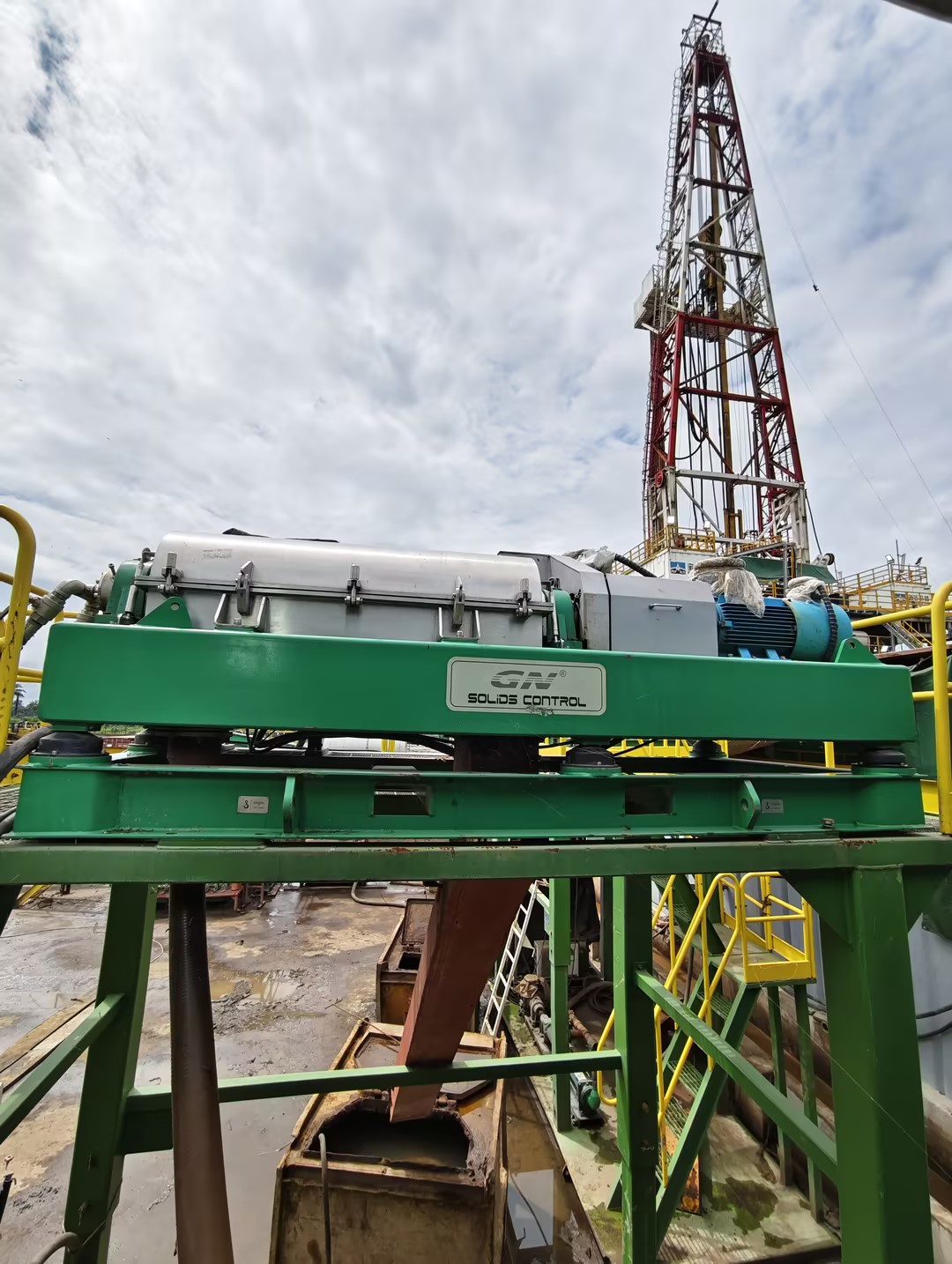

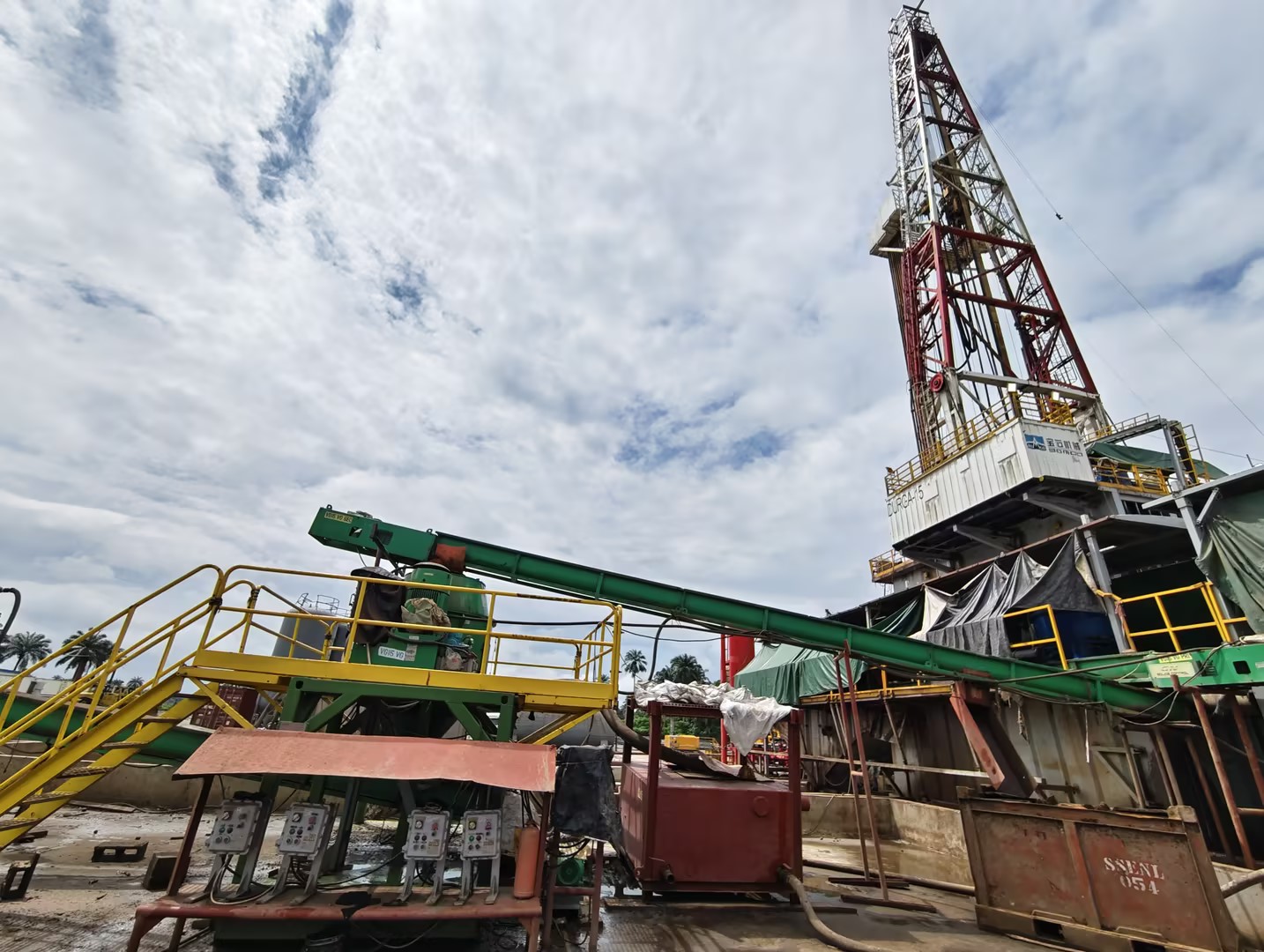

GN SOLIDS CONTROL is pleased to announce the successful delivery and commissioning of a complete drill cuttings treatment system to a leading drilling company in Africa. The system, designed to enhance environmental compliance and operational efficiency, includes two decanter centrifuges and one vertical cuttings dryer.

At the core of the solution are two GNLY363CD-VFD decanter centrifuges, which provide high-speed, variable-frequency separation for efficient solid-liquid separation. These are supported by a GNCD930G vertical cuttings dryer, which further reduces oil-on-cuttings and moisture content to meet stringent discharge standards.

The complete package also includes matching augers for material transfer, feed pumps for the centrifuges, and a dedicated wash pump for the dryer—all engineered by GN SOLIDS CONTROL to work as a seamless, integrated system.

This deployment underscores GN SOLIDS CONTROL’s commitment to delivering reliable, high-performance solids control and waste management solutions for the global drilling industry. By enabling effective drill cuttings processing, the system helps the African operator minimize waste volumes, reduce environmental footprint, and lower overall drilling costs.

GN SOLIDS CONTROL continues to expand its footprint in Africa, providing tailored equipment and technical support to help drilling companies achieve safer, cleaner, and more economical operations. With this project, GN SOLIDS CONTROL reinforces its role as a trusted partner in advancing sustainable drilling practices worldwide.