From April 23–25, GN Separation participated in IE EXPO CHINA 2025, held at the Shanghai New International Expo Centre. At Booth W5-076, GN showcased its latest innovations in material separation and sludge treatment technologies, attracting strong interest from visitors across the environmental, mining, and industrial sectors.

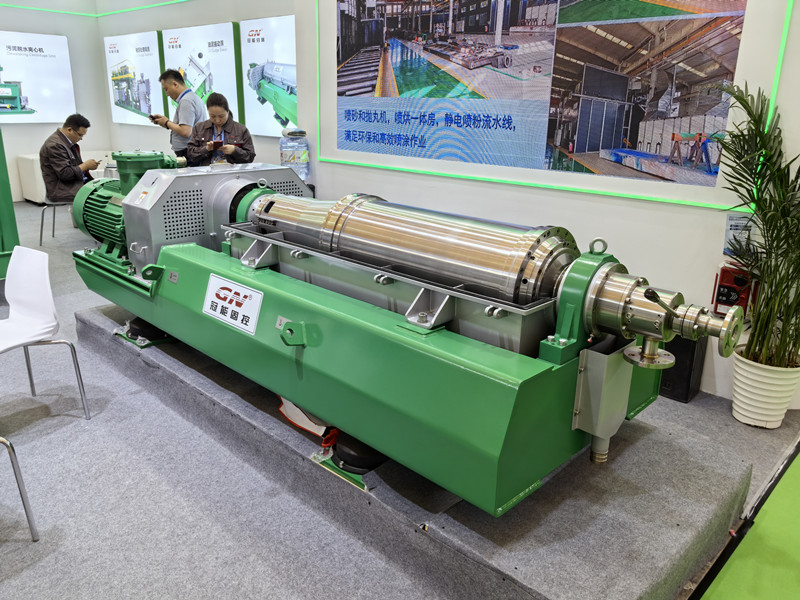

Among the exhibited equipment was GN’s 4th Generation Full Hydraulic Drive Decanter Centrifuge, designed for high-torque, continuous operations under demanding conditions. The hydraulic drive system ensures more precise bowl and scroll speed control, allowing stable separation performance even with fluctuating feed characteristics. Its robustness and flexibility make it particularly suitable for heavy-duty applications like oil sludge treatment and mineral tailings management.

GN also introduced its newly upgraded G Series 3-Phase Decanter Centrifuge. This model efficiently separates materials into oil, water, and solids phases simultaneously, making it ideal for industries requiring high-purity product recovery. Its compact footprint and simplified maintenance structure help end users lower operational costs without compromising separation accuracy.

In addition to centrifuges, GN exhibited its Solid Vacuum Pump, capable of transferring high-density sludge, drilling cuttings, and other challenging materials without relying on mechanical parts in contact with the conveyed material. This design reduces wear and extends equipment life, providing users with a low-maintenance solution for tough pumping tasks.

The IE EXPO CHINA 2025 event allowed GN Separation to demonstrate how its solutions contribute to more efficient, reliable, and economical material handling processes. The display of live equipment and real application discussions highlighted GN's commitment to supporting industries striving for higher environmental and operational standards.

Photos of GN’s stand and exhibited products drew significant attention during the event, showcasing GN’s practical engineering approach toward the future of material separation technology.